Integrated Supply Chain

Our supply chain offering features

- Rapid assessment

- market signals

- available assets and their capability

- business processes and their efficiency

- Rigorous managing processes

- improvement focused metrics

- organizational alignment to metrics

- skill building to run processes effectively

- Sophisticated systems technology supporting these processes

- demand management

- production planning

- inventory management

- scheduling

- logistics

Our rapid assessment determines your current capability and establishes the opportunity for improvement depicted in the graph above. Our knowledge of state of the art tools and

techniques, coupled with pragmatism gleaned from decades of hands-on operations, enables us to focus on what should be done, versus what could be done. We engage your

organization at their present supply chain understanding, and quickly build the tools and skills to fully utilize Tension Triangle Optimization.

The

tension comes form the trade-offs among customer service level,

inventory carrying costs, and manufacturing costs. Slimming

value chains drive higher service levels at the expense of higher

manufacturing costs and inventory carrying costs. Profitability

goals drive for lower manufacturing costs. Pressure for higher

capital returns drive for lower inventory. There is an optimum economic

balance of these forces, but it is not obvious. The science

of this relationship is complex mathematics, but easily managed

with the computing tools of today. The

tension comes form the trade-offs among customer service level,

inventory carrying costs, and manufacturing costs. Slimming

value chains drive higher service levels at the expense of higher

manufacturing costs and inventory carrying costs. Profitability

goals drive for lower manufacturing costs. Pressure for higher

capital returns drive for lower inventory. There is an optimum economic

balance of these forces, but it is not obvious. The science

of this relationship is complex mathematics, but easily managed

with the computing tools of today.

Usually, there is additional tension because the responsibility for the three tension items

resides in different organizations. Departmental goals are frequently in conflict. We engage leadership and the groups involved to align with the optimum business goals versus departmental subgoals. The examples below are typical of the more than 100 projects we have done

Elapsed time |

Project |

First year |

Benefit to |

Months |

cost, k$ |

benefit, k$ |

Cost ratio |

18 |

350 |

16000 |

46 |

6 |

90 |

10000 |

111 |

3 |

120 |

6000 |

50 |

2 |

50 |

5000 |

100 |

12 |

10 |

4000 |

400 |

6 |

175 |

3000 |

17 |

12 |

250 |

3000 |

12 |

12 |

350 |

1500 |

4 |

0.1 |

12 |

1000 |

83 |

24 |

200 |

800 |

4 |

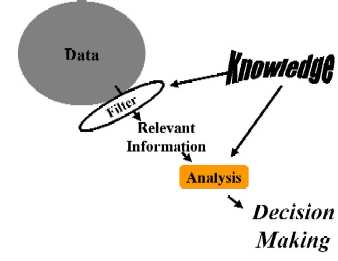

Knowledge Management Our knowledge management offering enables clients to manage their knowledge assets

with the same rigor as working capital and permanent investment. The intent is to create better decision making by having the best Corporate knowledge available at the location

and time of decision making. We supply tools, training, and methods for the spectrum of increasing knowledge structure:

- intelligent search and filter agents for business reconnaissance

- visualization and summarization tools for insight creation

- communities of "know-how" collaboration tools and methods for leveraging best practices

- engineered knowledge (models) as job aids for consistently better decision making

Clients have often achieved first year paybacks of greater

than ten times in the 500 plus projects we have done. This offering

frequently cuts across all functional areas and levels within your

organization. It has also be applied to specific trouble areas

The avalanche of data pouring from the new worldwide connectivity has turned business

reconnaissance upside down. . Previously there was frustratingly sparse data; now the relevant information is lost in a (also frustrating) sea of data too unwieldy to scan. We

install intelligent search and filter agents which tune themselves to your interest, getting better and better as you interact with them while gathering timely business intelligence,

The target of this offering is the "Relevant Information" component of the graphic above. Knowledge is delivered to the decision maker in a gray scale from passive to active.

Databases of best practices that describe ""how-to" and pointers to internal experts, teaming skill training, and collaboration infrastructure comprise our collaboration offering

We are an acknowledged leader in the development and application of expert systems, an active form of decision aid which brings community of practice expertise electronically

to the location of your decision making. We have installed high payback systems across all functions, we have working knowledge of almost all the available toolsets for building advanced models. New Product Development

We provide a staged gate process with focus on early and often market validation of a proposed new product or service. Our process allows the business team to have periodic

reviews with appropriate frameworks to guide resource and focus on the appropriate topics for the "gate" in the overall development process. Our market gates extension to

the classical staged gate development process enables management of the portfolio of downstream application opportunities. This feature is particularly valuable where long qualification times exist.

Our clients redirected a barrier resin product to niche markets where it was well suited and cost competitive versus an original broad market focus. The product has moved from

serious jeopardy to commercialization within six months. This refocus was critical to success as the business unit underwent significant downsizing. Agile Manufacturing We offer a market drumbeat assessment for installed or planned facilities, action plans,

and implementation to tune assets to their markets. Our methods are particularly useful for shared facilities, that is, production lines which make more than one grade of product

in the same equipment. We have proved methods for optimizing production campaign length, minimizing turnaround and changeover time, and establishing quick on-aim control.

We

have led clients through Make To Order (MTO) conversions of

Supply From Stock plants for achieving a quantum step in market

responsiveness with lower overall capitalization. . Understanding

of the size, variability, and frequency of orders drives selection

of equipment size for MTO. Variations of demand within the

lead time horizon determines whether peaking capacity or inventory

is the better method for coping. We

have led clients through Make To Order (MTO) conversions of

Supply From Stock plants for achieving a quantum step in market

responsiveness with lower overall capitalization. . Understanding

of the size, variability, and frequency of orders drives selection

of equipment size for MTO. Variations of demand within the

lead time horizon determines whether peaking capacity or inventory

is the better method for coping.

Our High Performing Work System methodology delivers dramatic productivity increases while raising morale. We have

proved methods for engaging the total workforce in business decision making. Alignment with key performance metrics for the company and for their group is raised to a core value for all levels of employees.

Market signal analysis of order signals drove reorganizing manufacturing in a plastics molding shop into work cells and unit dies vs. multiport operation. Dramatic reductions in

inventory generated cash flow. streamlined manufacturing raised earnings to an acceptable level. |